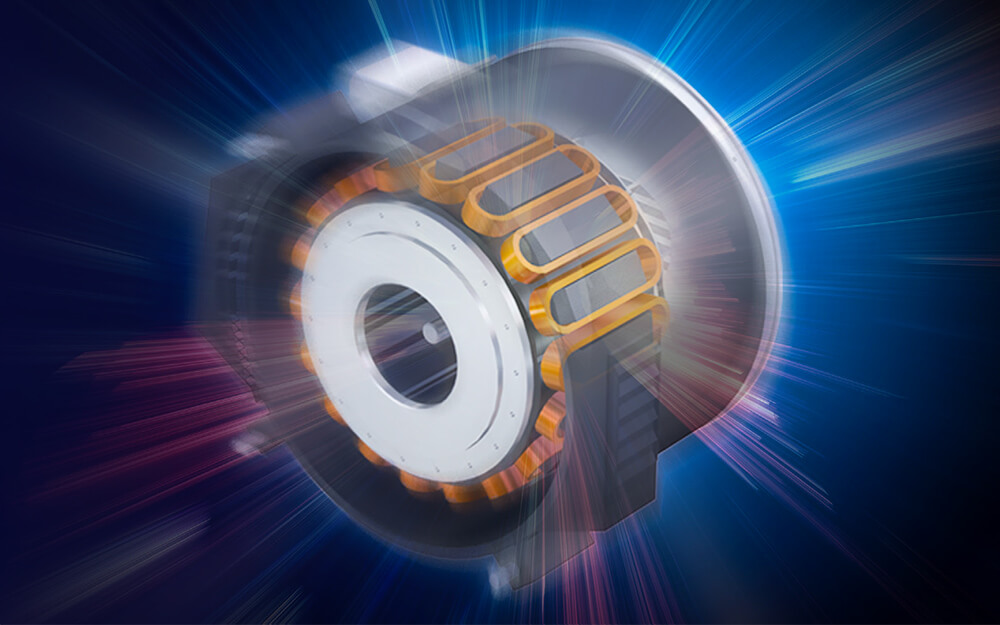

PM MOTOR

With powerful driving core, it is more energy-saving and energy-saving

The biggest advantage of permanent magnet variable frequency air compressor is energy saving by 10%~35% in average. It depends on the working condition of the air compressor and the setting of the frequency converter.

If the air consumption fluctuates, the energy-saving effect is better. Using a high-efficiency and energy-saving control system, the starting current is small and reduce the impact on the motor and electrical components; the life of the motor is extended, and the impact on the equipment and machinery is relatively reduced.

- Permanent Magnet Motor

- The biggest advantage of permanent magnet variable frequency air compressor is energy saving by 10%~35% in average. It depends on the working condition of the air compressor and the setting of the frequency converter.

- Most Efficient, Energy-Saving

- Air compressor a must-have equipment of factory, but it is with high power consumption. To enhance the efficiency of operation matters the cost and competitiveness, demand for energy saving is high and a must; variable speed air compressor changes the rotating speed of the motor with an variable speed.

- Seamless steel pipe line design

- DYNA screw type air compressor adapted the latest technique of connector of bent pipes, with audio frequency monitored by national certified laboratory, DYNA developed exclusive design to use seamless steel pipeline for all series. Quality is guaranteed, no oil leakage.

- Cooling system

- Oil filtration + thermostat = anti-emulsification, no degeneration. Design according to subtropical weather, optimal tipping point of water evaporation be fixed, cycling oil stay pure, no emulsification, no degeneration, normal machine operation insured.

- Oil/air separator system

- Pressure retaining valve reduce the pressure difference, the oil particles atomized and diffused after impact, with patented mechanical oil tank separation, the air discharged with oil content below 2 ppm.

- Dust filtration net System

- DYNA R&D team designed fore-installed dust infiltration net, Capture efficiency it’s over 90%, efficiently blocked the dust from the machine. It extends durability of consumables, light in weight, easy installation and replacement, small in pressure loss, big in air volume processed. It saves a lot of equipment and man power.

| Model Number | F.A.D. at Working Pressure | Motor Power | Air Outlet Pipe Dia | Compressor Dimensions | Net Weight | |||

|---|---|---|---|---|---|---|---|---|

| 8kg/cm² | ||||||||

| m³/min | cfm | kW | HP | inch | L × W × H (mm) | kgs | ||

| E120 | ES120P-22VS | 3.5 | 123 | 22 | 30 | 1 1/4 | 1430 × 950 × 1150 | 523 |

| ES120D-22VS | 4.0 | 141 | 22 | 30 | 1 1/4 | 1430 × 950 × 1150 | 623 | |